- Product ID: 38990

- Suitable For: levelling and smoothing most new and existing internal subfloors

- Area of use: INT & EXT

- Application Method: trowel/float

- Time to full cure: 12 hours

- Volume: 22kg

- Container Type: bag

- Type: concrete compound

- Colour: Grey

- Brand: Ardex

- Manufactuer: Ardex

- Box Size: 1

ARDEX K 40 HB is a versatile, fiber-reinforced, high-build levelling and smoothing compound designed for a wide range of applications, with thicknesses ranging from 3mm to 40mm. This advanced compound hardens rapidly, allowing for a swift turnaround in construction or renovation projects. It is suitable for use on most new and existing internal subfloors, including concrete, cement/sand screeds, anhydrite screeds, stone, terrazzo, ceramic tiles, and appropriate timber floors. ARDEX K 40 HB is particularly useful for levelling uneven, damaged, or rain-damaged in-situ concrete subfloors, as well as for adjusting tolerances or addressing camber issues between floors, slabs, or pre-cast concrete. The product’s rapid hardening properties allow for foot traffic in as little as 2 hours, regardless of the thickness applied. It also enables the installation of resilient floor coverings over thinner applications (up to 5mm) after just 6 hours, with thicker applications (up to 40mm) being ready for covering after 48 hours. Ceramic floor tiles can be fixed as soon as the surface has achieved sufficient strength and hardness, typically within 2 hours after application.

Key Points:

- Versatile Application: Suitable for thicknesses from 3mm to 40mm, ARDEX K 40 HB can level and smooth a variety of internal subfloors, including concrete, screeds, stone, terrazzo, and timber floors.

- Rapid Hardening: The compound hardens quickly, allowing foot traffic within 2 hours of application, making it ideal for time-sensitive projects.

- Floor Covering Readiness: Resilient floor coverings can be installed over applications up to 5mm after 6 hours, and over thicker applications up to 40mm after 48 hours.

- Ceramic Tile Compatibility: Ceramic tiles can be installed as soon as the surface has gained sufficient strength, typically 2 hours after application.

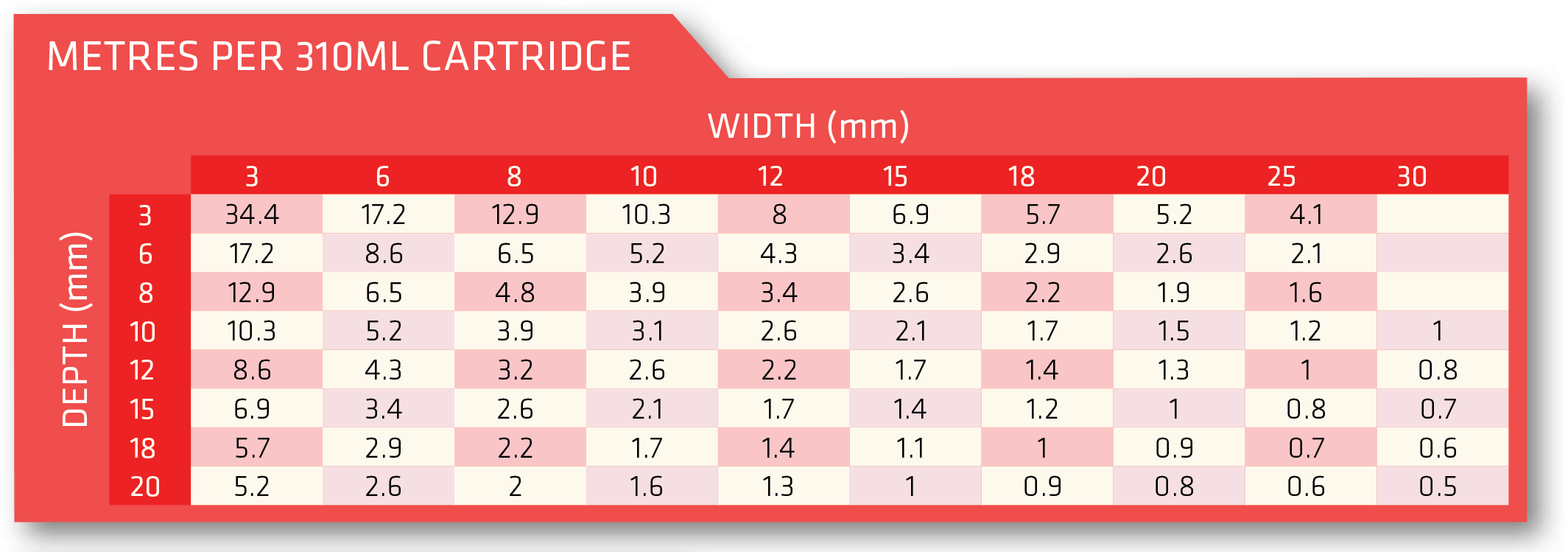

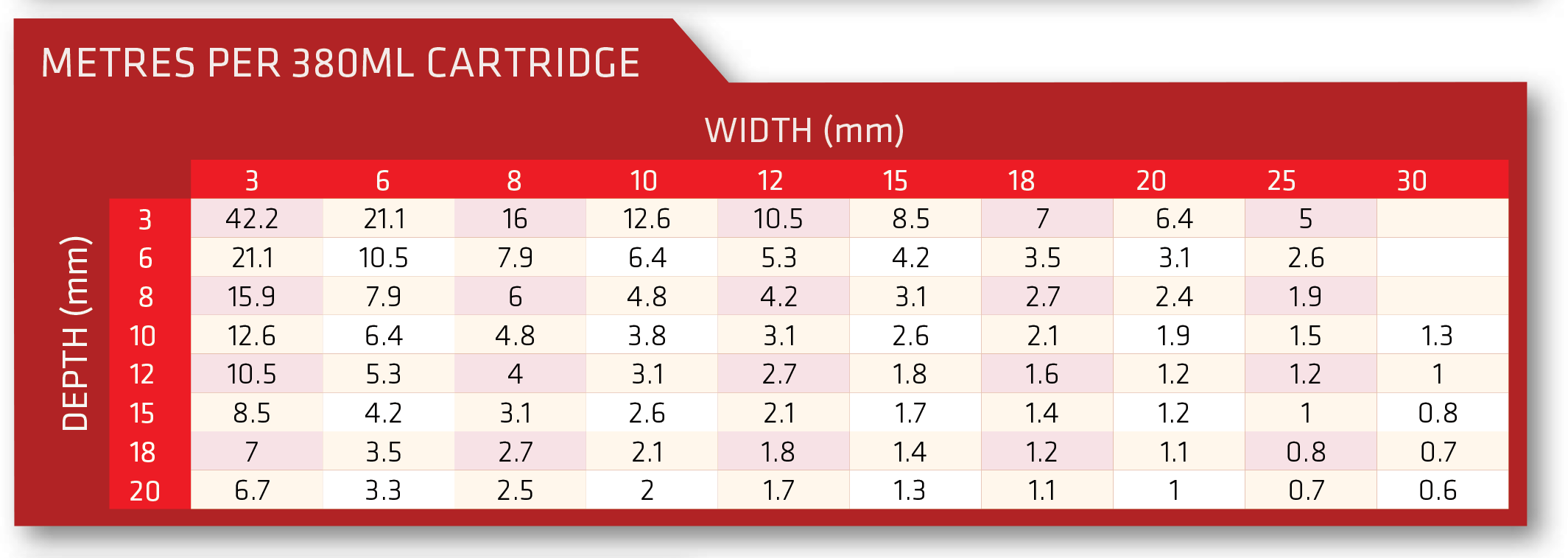

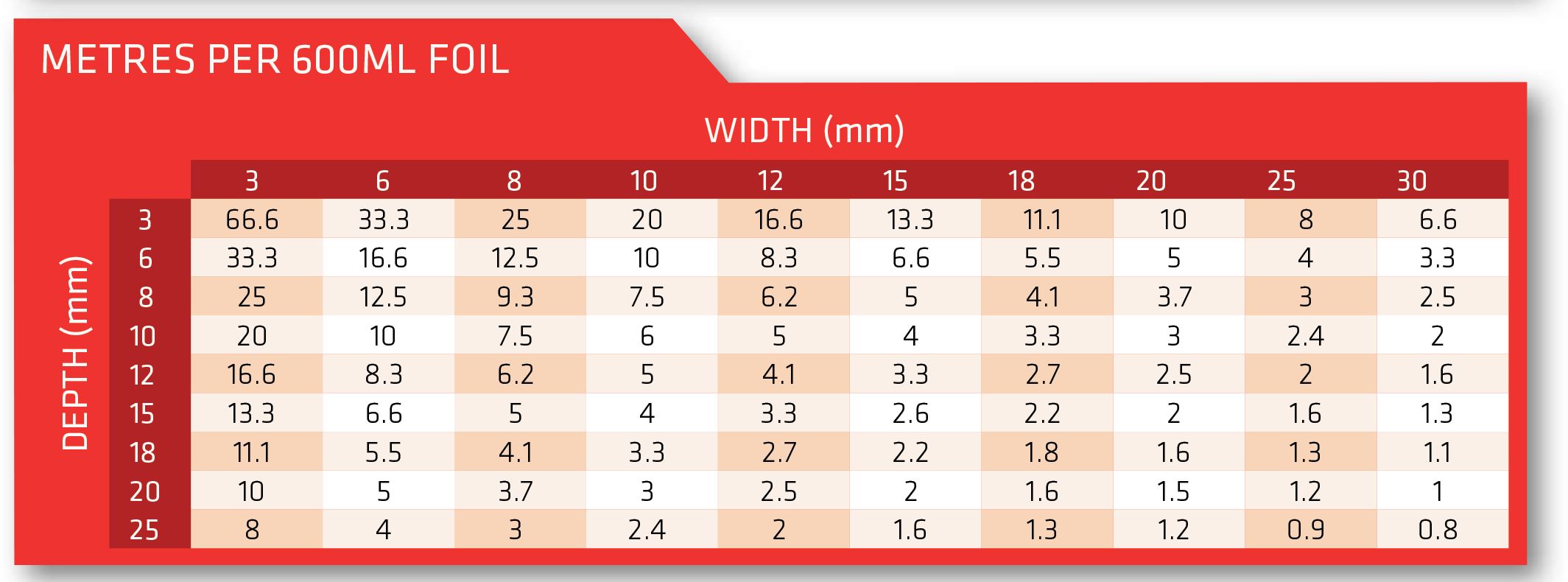

Coverage: A 22kg bag of ARDEX K 40 HB will cover approximately 4m² at a thickness of 3mm, with a consumption rate of 1.88kg per mm per m². This coverage estimate is based on application over a flat, level surface. If the surface is rough or uneven, additional material may be required to achieve the desired level and smoothness.

For more in our range of concrete products, click here. For see more of our Ardex range, click here.

Alternatively, you can visit the Ardex website here.

Tags: k40, Ardex k40, Ardex K40 HB

ARDEX K40HB is designed to level and smooth most new and existing internal subfloors in a single application. It is suitable for use on a variety of surfaces, including concrete, cement/sand screeds, anhydrite screeds, stone, terrazzo, ceramic tiles, and appropriate timber floors. Additionally, it can be used to address issues with uneven, damaged, or rain-damaged in-situ concrete subfloors, as well as to correct tolerances or camber problems between floors, slabs, or pre-cast concrete.

Substrate Preparation

Before applying ARDEX K40HB, ensure the subfloor is clean, sound, and free from dust, plaster, grease, polish, and any water-softenable or loosely adhered materials. Any adhesive residues must be hard, well-adhered, and unaffected by water. Use a suitable degreaser to remove contaminants like polish, wax, grease, and oil. Subfloors in direct contact with the earth must have an effective damp proof membrane (DPM). If the DPM is missing, damaged, or the substrate is damp, consult the ARDEX DPM 1 C, ARDEX DPM 1 C R, or ARDEX MVS 95 datasheet for guidance.

Priming

All surfaces must be primed to extend working time, maintain flow life, and prevent air bubbles in the levelling compound. For cement/sand or gypsum screeds, mix ARDEX P 51 Primer with water at a ratio of 1:3. For concrete subfloors, the ratio should be 1:2. For timber, use undiluted ARDEX P 51 Primer and allow it to dry. Note that ARDEX K 40 HB can be applied up to 6mm thick over gypsum or timber subfloors. For smooth, dense, or non-absorbent subfloors like ARDEX Damp Proof Membranes or power-floated concrete, ARDEX P 4 Primer is recommended. For ARDEX DPMs with smoothing applications between 3mm to 6mm or non-absorbent subfloors where ARDEX K 40 HB is applied up to 10mm, use ARDEX P 4 or ARDEX P 82 Primer. For thicker applications, use ARDEX R 3 E with ARDEX Fine Aggregate as the primer coat. When applying over flooring grade asphalt, the surface must be sound, cleaned with a neutral cleaner, primed with ARDEX P 82 Primer, and applied between 3-5mm thick.

Timber Floors

Plywood must be rigid, dry, and capable of supporting anticipated loads according to BS 8203 for resilient flooring and BS 5385-3 for ceramic tiling. Seal the backs and edges of plywood with polyurethane varnish when fixing ceramic tiles. Securely screw down loose boards before levelling. If the timber floor is uneven or worn, pre-level with ARDEX K 40 HB, then screw-fix a minimum of 6mm thick flooring-grade plywood or tile backing board before installing resilient flooring or ceramic tiles. Ensure subfloor ventilation is adequate to prevent deterioration. Allow 1 to 12 hours of drying time depending on timber porosity. For plywood free from adhesion barriers, ARDEX K 40 HB can be applied up to 6mm thick as a smoothing layer. For tongue and groove floorboards or timber floors in conservatories or non-domestic areas, overlay with plywood or consult the ARDEX FA 20 datasheet. Tongue and groove boards must be 22mm thick. Avoid using impregnated boards as they prevent primer penetration. In domestic and light-duty installations, chipboard must meet the latest BS EN 312 standard and be of suitable flooring grade. Sand and vacuum chipboard thoroughly to remove barriers to adhesion before priming with undiluted ARDEX P 51 Primer. If the primer does not soak into the board, adhesion may be compromised; consult the board supplier if in doubt.

Mixing

Use between 3½ and 3¾ litres of water per 22kg bag of ARDEX K 40 HB. Add the powder to the water in a clean container, stirring thoroughly until a lump-free consistency is achieved. Use an ARDEX mixing paddle with a 10mm chuck slow-speed (600-1000 rpm) electric drill for efficient mixing. For thicker applications or in cold conditions, use the minimum amount of water.

Application

Apply ARDEX K 40 HB at temperatures above 5°C. Pour the mixed compound onto the prepared subfloor and use a pin steel finishing trowel or float to spread and smooth it. The product’s extended workable wet edge time allows fresh material to be trowelled into pre-applied material up to 30 minutes after application. Protect the freshly applied compound from direct sunlight or drafts to avoid premature drying.

Applications Over Underfloor Heating

Underfloor heating systems must be installed per BS 8204 Part 1 and BS EN 1264 standards. The system should be commissioned according to the manufacturer’s instructions, and the temperature lowered to room level (not below 15°C) before applying ARDEX K 40 HB and floor coverings. After installation, gradually increase the temperature to avoid thermal shock. ARDEX K 40 HB can also encapsulate under-tile heating cables or mats on prepared subfloors before ceramic tile installation. For information on suitable underfloor heating systems, contact ARDEX Technical Support.

Encapsulating Low-Profile Waterfed Heating Systems

The floor should comply with Part L of the building regulations, be fully load-bearing with a deflection of no more than L/360 (L/720 for natural stone), and leveled to SR1 or better before installing underfloor heating. Ensure castellated systems are seated on a level, load-bearing surface. After securing and pressurizing pipes, install ARDEX K 40 HB to the height recommended by the heating manufacturer. Calcium sulfate boards should be securely installed and free from movement, with a perimeter movement joint in place. If bonding boards to the floor, prime both sides with ARDEX P 51 (1:3) before applying tile adhesive. Otherwise, only the surface receiving the levelling compound needs priming. Avoid installing onto metallic surfaces like aluminum plates. For tiling and flooring, cover the heating pipes with ARDEX K 40 HB to a height of 6 to 10mm. A bonded uncoupling system can be used for tiles where lateral movement is expected. Install movement joints according to industry standards. Ensure the heating system is commissioned correctly and the flooring chosen is suitable for both the environment and service duties. Contact the manufacturer for specific recommendations.

You must be logged in to post a review.

| Elementlength | |||||||

| up to 1,5 m |

up to 2,5 m |

up to 3,5 m |

up to 4,5 m |

up to 2,5 m |

up to 3,5 m |

up to 4,5 m |

|

| Type of window frame material |

Minimum witdth of joints for a butled mounting b in mm |

Minimum witdth of joints for a inner mounting b in mm |

|||||

| Hard PVC (white) | 10 | 15 | 20 | 25 | 10 | 10 | 15 |

| Hard PVC and PMMA (dark) (colour extruded) |

15 | 20 | 25 | 30 | 10 | 15 | 20 |

| Hard PUR integral foam | 10 | 10 | 15 | 20 | 10 | 10 | 15 |

| Wood-aluminium-window | 10 | 10 | 15 | 20 | 10 | 10 | 15 |

| Aluminium-plastic sandwich frame (bright) |

10 | 10 | 15 | 20 | 10 | 10 | 15 |

| Aluminium-plastic sandwich frame (dark) |

10 | 15 | 20 | 25 | 10 | 10 | 15 |

| Wooden window frame | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

Related Products

-

From: £180.24 inc. VAT

£150.20 ex. VAT -

-

-

-

From: £6.59 inc. VAT

£5.49 ex. VAT

From: £6.59 inc. VAT

£5.49 ex. VAT

From: £2.69 inc. VAT

£2.24 ex. VAT

From: £3.12 inc. VAT

£2.60 ex. VAT

From: £3.11 inc. VAT

£2.59 ex. VAT

From: £8.03 inc. VAT

£6.69 ex. VAT

From: £3.11 inc. VAT

£2.59 ex. VAT

From: £13.14 inc. VAT

£10.95 ex. VAT

From: £3.11 inc. VAT

£2.59 ex. VAT

From: £6.59 inc. VAT

£5.49 ex. VAT

From: £6.59 inc. VAT

£5.49 ex. VAT

From: £2.69 inc. VAT

£2.24 ex. VAT

From: £3.12 inc. VAT

£2.60 ex. VAT

From: £3.11 inc. VAT

£2.59 ex. VAT

From: £8.03 inc. VAT

£6.69 ex. VAT

From: £3.11 inc. VAT

£2.59 ex. VAT

From: £13.14 inc. VAT

£10.95 ex. VAT

From: £3.11 inc. VAT

£2.59 ex. VAT

From: £6.59 inc. VAT

£5.49 ex. VAT

From: £6.59 inc. VAT

£5.49 ex. VAT

From: £2.69 inc. VAT

£2.24 ex. VAT

From: £3.12 inc. VAT

£2.60 ex. VAT

From: £32.23 inc. VAT

£26.86 ex. VAT

From: £32.23 inc. VAT

£26.86 ex. VAT

-

Rated 5.00 out of 5

£3.19 inc. VAT

£2.66 ex. VATBond-It De-Bond Mate is A non-drip gel formula for the complete removal of cured silicone sealant, particularly when silicone has been accidentally smeared over glass, ceramics or countertops. Removes all types of silicone sealant, leaving surfaces ready for re-sealing. For all other Bond-it products on our website, please click here. For any further information, you may need on Bond-it, please visit their website here. -

Rated 5.00 out of 5

£2.94 inc. VAT

£2.45 ex. VATBond-it Flash Mate Lead Silicone is a low modulus neutral cure fast-skinning, roof sealant It is a high-performance neutral cure silicone sealant, specifically designed for use with roofing products both modern and traditional. For all other Bond-it products on our website, please click here. For an alternative silicone for lead, click here. For any further information you may need on Bond-it, please visit their website here. -

£9.06 inc. VAT

£7.55 ex. VATEverbuild 565 Clean Room Silicone is a neutral cure, low modulus, odourless sealant that adheres to a wide range of surfaces. Advantages - Mould Resistant for up to 10 years. - Bacterial resistance. - Excellent tooling and slow skinning properties. - Excellent adhesion properties to most surfaces. - Non-slump formula. - Excellent weathering properties. For application guns click here. For application tools click here. For all other Everbuild products on our website, please click here. For any further information on Everbuild products, please visit -

Rated 5.00 out of 5

£6.78 inc. VAT

£5.65 ex. VATEverbuild Aqua Mate Sealant is a high modulus, reactive curing silicone sealant specially designed for aquariums. It remains permanently flexible & forms a watertight seal. Advantages - Everbuild Aqua Mate is free from fungicide and solvent - will not harm fish. - Fast cure - gives quick early strengths. - Extremely low dirt pick up. - Will withstand continuous water immersion. For application guns for this product, please click here. For all other Everbuild products on our site, please view here. For any further information on any Everbuild products, ple

Reviews

There are no reviews yet.