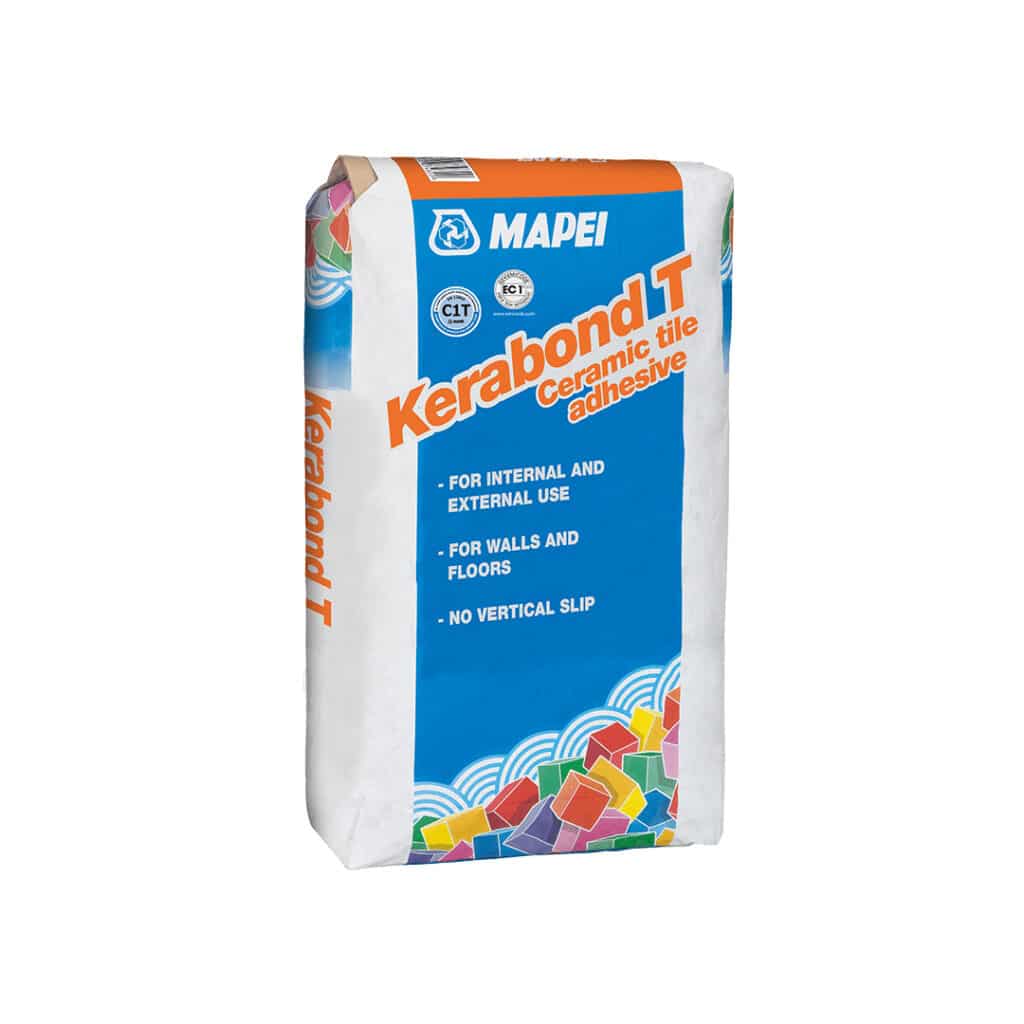

- Suitable For: bonding of all types of ceramic tiles

- Area of use: INT & EXT

- Application Method: trowel

- Volume: 20kg

- Container Type: bag

- Type: adhesive

- Colour: 2 colours

- Brand: Mapei

- Manufactuer: Mapei

- Box Size: 1

Adesilex P9 is a grey or white powder made from cement, fine-graded aggregates, synthetic resins, and special additives developed in MAPEI’s Research and Development Laboratories. When mixed with water, it creates a mortar that is easily workable and highly thixotropic, allowing for vertical application without sagging or slipping, even with heavy tiles. It offers excellent adherence to various building materials and hardens with minimal shrinkage. Additionally, Adesilex P9 features an extended open time and is resistant to water and frost.

Key Points:

Adesilex P9 is a grey or white powder composed of cement, fine aggregates, synthetic resins, and special additives.

It forms a highly thixotropic mortar that can be applied vertically without sagging or slipping, even with heavy tiles.

The product adheres perfectly to all common building materials and hardens with minimal shrinkage.

Adesilex P9 has an extended open time and is resistant to water and frost.

For more information about Mapei, please visit their website here.

For our range of Mapei products, please click here. For more in our range of admixtures, please click here.

Adesilex P9 is ideal for the interior and exterior bonding of all types of ceramic tiles, including thin porcelain tiles, single-red, double-red, clinker tiles, bricks, and mosaics on floors and walls. It is also suitable for spot bonding insulating materials such as expanded polyurethane, expanded polystyrene, glass wool, and sound-deadening panels.

Application Examples:

Bonding ceramic tiles, stone materials (moisture-resistant), and mosaics on various substrates, including:

Conventional renders or cementitious mortar walls. Interior aerated concrete block walls. Gypsum or anhydrite surfaces after applying Primer G. Gypsum board. Underfloor heating systems encapsulated in a screed, concrete, or cementitious smoothing compound. Cementitious screeds that are sufficiently cured and dry. Interior painted walls provided the paint is firmly adhered. Tile-on-tile installations of existing flooring using both ceramic and natural stone tiles, as long as they are well bonded to the substrate and free of cracks. Bonding small-sized tiles in swimming pools and basins.

Preparation of the Substrate

All substrates must be flat, sound, and free of loose particles, grease, oils, paints, wax, and other contaminants. Cementitious substrates should not continue to shrink after the installation of ceramic tiles. Renders must cure for at least 2 weeks, and cementitious screeds must be cured for at least 3-4 weeks unless special MAPEI binders like Mapecem, Mapecem Pronto, Topcem, or Topcem Pronto have been used. If surfaces are too warm or exposed to direct sunlight, dampen them with water to cool down. Gypsum substrates and anhydrite screeds must be perfectly dry (maximum residual moisture of 0.5%), sufficiently hardened, and free from laitance. It is essential to treat them with Primer G or Eco Prim T Plus.

Mixing

Mix Adesilex P9 with clean water until a smooth, lump-free paste is achieved. Allow it to rest for approximately 5 minutes, then re-stir. Use 29-31 parts of water for every 100 parts by weight of Adesilex P9, which equals 5.8-6.2 litres of water for every 20 kg of powder. When mixed this way, Adesilex P9 has a pot life of about 8 hours.

Applying the Product

Adesilex P9 is applied to the substrate using a notched trowel. Select a trowel that will achieve 65-70% coverage of the back of the tiles for internal walls and 100% coverage for floor areas and all external or wet areas. For good adhesion, first spread a thin layer of Adesilex P9 on the substrate using the straight edge of the trowel, then immediately apply the required thickness using a suitable notched trowel based on the type and size of the tiles. For external tiling and installations in swimming pools or basins filled with water, back-butter the adhesive onto the back of the tile to ensure complete contact.

Installing the Tiles

Do not wet the tiles before installation; only if they are dusty should they be dipped in clean water and dried before fixing. Install tiles with firm pressure to ensure good contact with the adhesive. Under normal temperature and humidity conditions, the open time of Adesilex P9 is approximately 30 minutes. Unfavourable weather conditions (such as strong sun, drying wind, or high temperatures) or a highly absorbent substrate can reduce the open time to just a few minutes. It is crucial to check that a skin has not formed on the adhesive’s surface. If a skin has formed, refresh the adhesive by re-spreading it with a notched trowel. Avoid wetting the adhesive once a skin has formed, as this will create a non-adhesive film. If necessary, adjust tiles within 60 minutes of installation. Tiling installed with Adesilex P9 should not be washed or exposed to rain for at least 24 hours and must be protected from frost and strong sunlight for at least 5-7 days.

Spot-Bonding Insulating Materials

For spot-bonding sound-deadening or insulating panels, apply Adesilex P9 with a trowel or float.

You must be logged in to post a review.

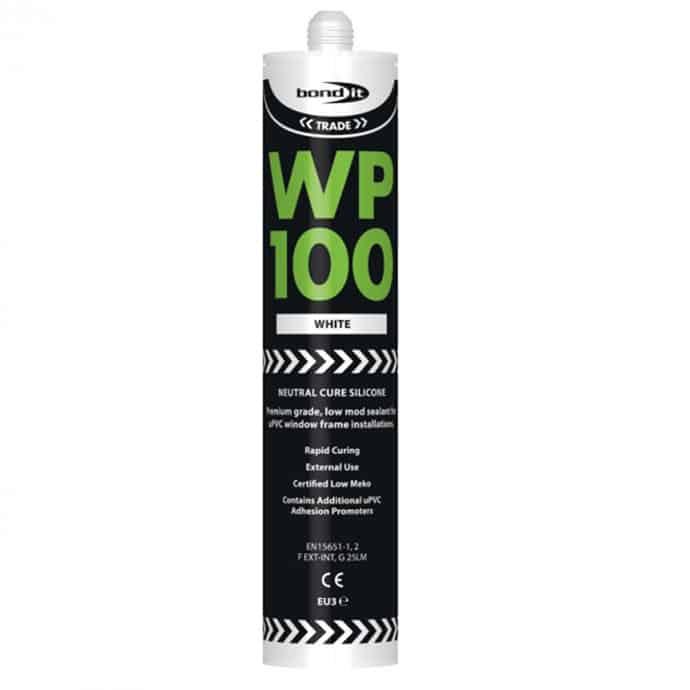

| Elementlength | |||||||

| up to 1,5 m |

up to 2,5 m |

up to 3,5 m |

up to 4,5 m |

up to 2,5 m |

up to 3,5 m |

up to 4,5 m |

|

| Type of window frame material |

Minimum witdth of joints for a butled mounting b in mm |

Minimum witdth of joints for a inner mounting b in mm |

|||||

| Hard PVC (white) | 10 | 15 | 20 | 25 | 10 | 10 | 15 |

| Hard PVC and PMMA (dark) (colour extruded) |

15 | 20 | 25 | 30 | 10 | 15 | 20 |

| Hard PUR integral foam | 10 | 10 | 15 | 20 | 10 | 10 | 15 |

| Wood-aluminium-window | 10 | 10 | 15 | 20 | 10 | 10 | 15 |

| Aluminium-plastic sandwich frame (bright) |

10 | 10 | 15 | 20 | 10 | 10 | 15 |

| Aluminium-plastic sandwich frame (dark) |

10 | 15 | 20 | 25 | 10 | 10 | 15 |

| Wooden window frame | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

From: £3.11 inc. VAT

£2.59 ex. VAT

-

£3.19 inc. VAT

£2.66 ex. VATBond-It De-Bond Mate is A non-drip gel formula for the complete removal of cured silicone sealant, particularly when silicone has been accidentally smeared over glass, ceramics or countertops. Removes all types of silicone sealant, leaving surfaces ready for re-sealing. For all other Bond-it products on our website, please click here. For any further information, you may need on Bond-it, please visit their website here. -

£2.94 inc. VAT

£2.45 ex. VATBond-it Flash Mate Lead Silicone is a low modulus neutral cure fast-skinning, roof sealant It is a high-performance neutral cure silicone sealant, specifically designed for use with roofing products both modern and traditional. For all other Bond-it products on our website, please click here. For an alternative silicone for lead, click here. For any further information you may need on Bond-it, please visit their website here. -

£9.06 inc. VAT

£7.55 ex. VATEverbuild 565 Clean Room Silicone is a neutral cure, low modulus, odourless sealant that adheres to a wide range of surfaces. Advantages - Mould Resistant for up to 10 years. - Bacterial resistance. - Excellent tooling and slow skinning properties. - Excellent adhesion properties to most surfaces. - Non-slump formula. - Excellent weathering properties. For application guns click here. For application tools click here. For all other Everbuild products on our website, please click here. For any further information on Everbuild products, please visit -

£6.78 inc. VAT

£5.65 ex. VATEverbuild Aqua Mate Sealant is a high modulus, reactive curing silicone sealant specially designed for aquariums. It remains permanently flexible & forms a watertight seal. Advantages - Everbuild Aqua Mate is free from fungicide and solvent - will not harm fish. - Fast cure - gives quick early strengths. - Extremely low dirt pick up. - Will withstand continuous water immersion. For application guns for this product, please click here. For all other Everbuild products on our site, please view here. For any further information on any Everbuild products, ple

Reviews

There are no reviews yet.